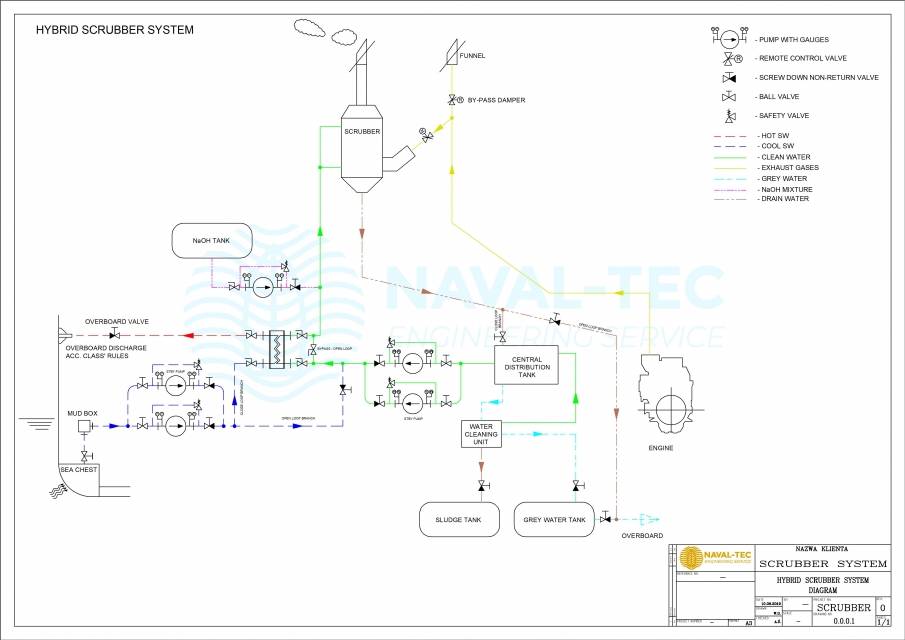

In accordance with the requirements of the Sulfur Emission Control Areas "SECA" introduced on January 1, 2015, all vessels in the "SECA" area must reduce sulfur emissions. Achieving these assumptions is possible by installing an exhaust gas filter system (scrubber systems). Naval-Tec is able to design and perform the installation on the ship. The system is used to remove harmful substances from exhaust gases before they are released into the environment.

There are two core methods for Exhaust Gas Cleaning Systems in marine industry:

At Naval-Tec we use our tailor-made solutions to integrate Scrubber Systems in the most effective way. To optimize the time needed for installation of the system, our trained and highly qualified team is able to perform their job as well during a temporary stop in the harbor as at the time of the cruise, regardless to the work of the crew on the ship.

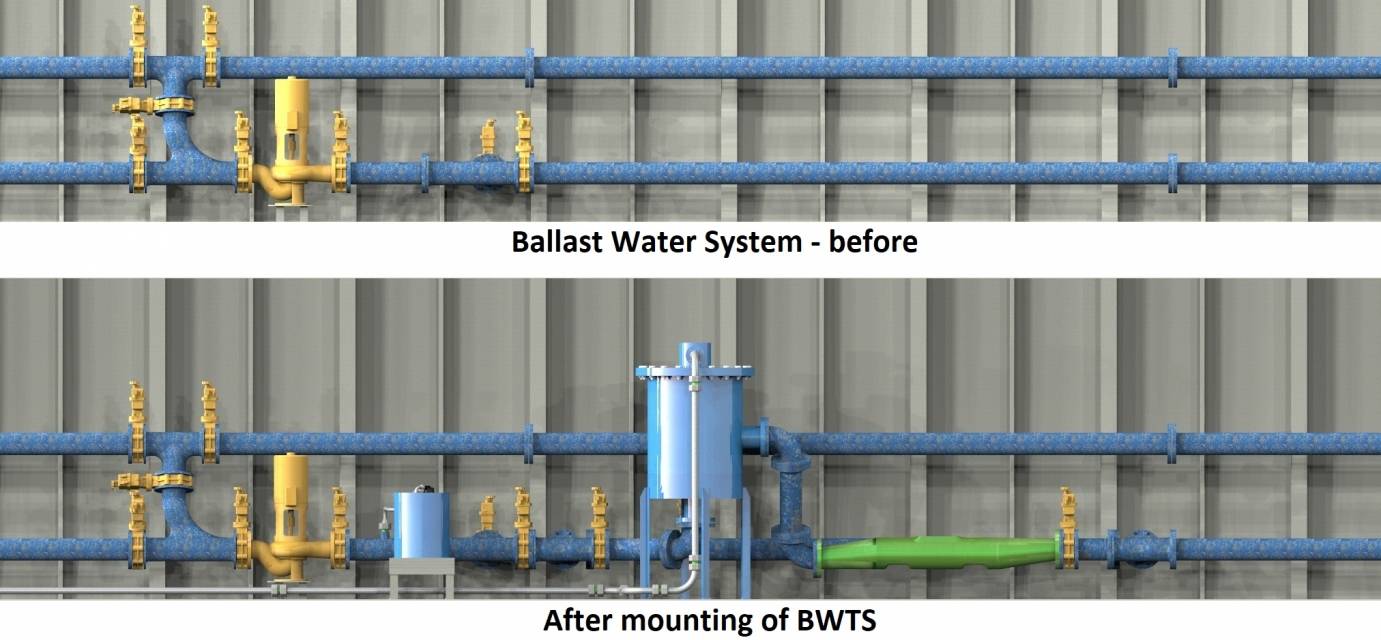

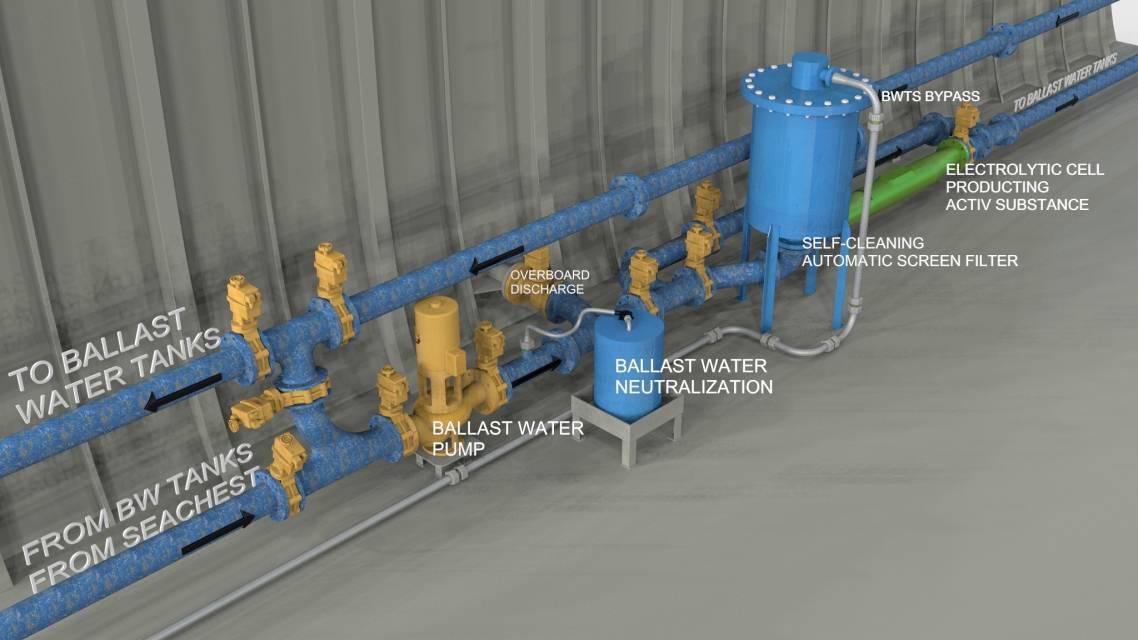

With respect to the best interest of the natural environment, the International Maritime Organization (IMO) announced that all sea vessels of 400 GT or more must comply with the standard D1 which concerns ballast water exchange. Ships are required to manage their ballast tanks to remove or render harmless the ballast water discharge of invasive species.

The most effective way to meet these expectations is to install a Ballast Water Treatment System (BWTS). This method is environmentally friendly, chemical-free, future-proof and has moreover no safety risks.

Naval-Tec ballast water management contains:

Electrical design including power and instrument control is our strength. This discipline is ensured by Elbudmed-marine leading electrical design provider. Diagrams, layouts, arrangements, calculations, I/O, main distribution lists are our daily bread.

Wide scope of possible responsibilities:

We put emhasis to system integration which contains e.g.:

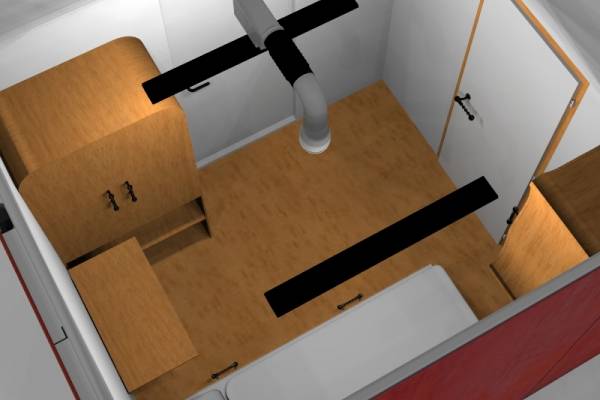

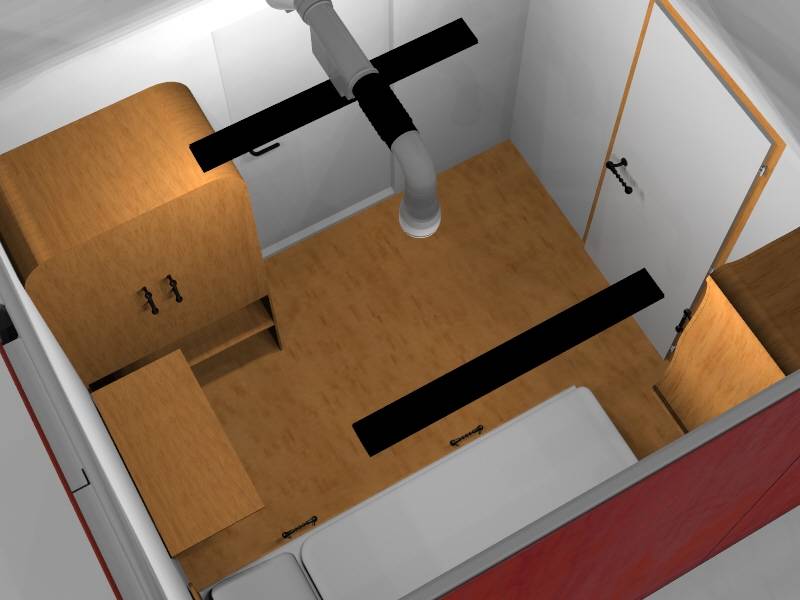

Shipping containers can accommodate a number of people in spite of limited space. This solution is getting more popular nowadays due to its wide range advantages. Below you can find a list of basic features of the Accommodation Containers:

Naval-Tec has lots of experience in design of accommodation containers. We always tailor our approach to the customer's requirements.

It is a technology for gathering information about the shape of the object and it's appearance using a line of laser light. Scanners create „point clouds” from objects surfaces which are later defined as a millions of measurement points in XYZ axes which after scanning are ready to work with.

With this useful tool it takes just one visit on board or wherever it's needed to collect data and use it to analyze and construct 3D models.

Using 3D scanner we are ready to process the results (point clouds) into specific software and start 3D modeling what gives us an excellent background to prepare full workshop documentation.

On site supervision and quality inspection is essential to guarantee the high level of standard required by the Clients. The detailed progress is closely monitored by the project management team and regular site visits are included. Naval-Tec's project management team operate upon an efficient and proven methods that guarantees the highest quality of ship construction.

Our on-site quality supervision services:

Naval-Tec treats supervision and consulting and every ship construction project as a unique case and so we offer customized services according to client’s needs and the nature of the specified project. At the same time our experienced team of professionals is in position to examine and carry out client’s requests immediately and effectively.